Newsletter April - June 2019

PCTE on the Road

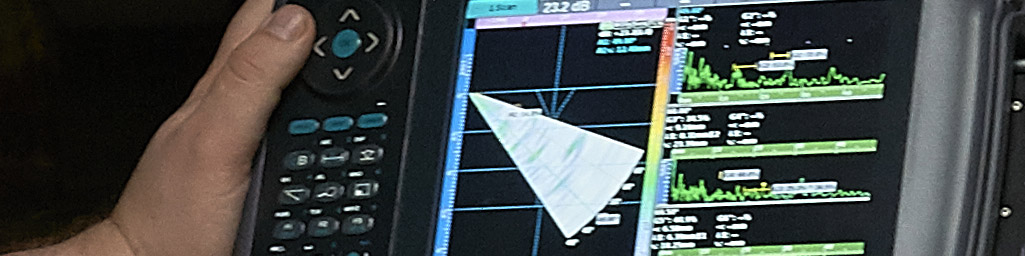

We were delighted to host Dolphitech CEO Christian Backe, all the way from Norway. Christian along with our Industrial-NDT Sales Manager Warren Villarosa, undertook a tour across Australia and NZ to showcase the Dolphicam2 - the most sophisticated and technologically advanced ultrasonic sound imaging camera on the market. The Dolphicam is flexible, adaptable and intuitive; made with expanded capability in mind and designed to be learned quickly by experts and non-experts alike. The tour was a great success, not only did we have the chance to show off this new piece of equipment to our fantastic customer base, Christian also managed to take in some sights of Australia and New Zealand for the first time.

Blog: Overview of High Temperature Hydrogen Attack

High-Temperature Hydrogen Attack (HTHA) is an issue occurring in steels operating at elevated temperatures of above 205 deg C in Hydrogen-rich environments. HTHA occurs when Hydrogen molecules dissociate and diffuse into the steel, where they react with the carbon present to form Methane (CH4). The Methane then gathers at the grain boundaries of the steel as it cannot diffuse out of the steel. The removal of Carbon from the matrix (decarburisation) can occur at the surface or internally in the element. Surface decarburisation is characterised by a loss of hardness and an increase in ductility. This generally occurs where temperatures are high, but the partial pressure of the Hydrogen is low.

Internal decarburisation, however, can cause voids, cracks or fissures and therefore the substantial loss of mechanical properties. In this case, precipitates at the grain boundaries can cause further weakening of the crystalline structure. Conditions that favour this outcome can be lower temperatures with a higher concentration of Hydrogen. Steels that contain Cr, Mo and V can increase the resistance to this type of attack. The Nelson curves were created in 1949, and it specifies the temperatures and Hydrogen concentrations for different compositions of steel whereby they would be safe from HTHA. They were created using empirical data observed from experiments. However, with the continued development of modern steels, these diagrams have become less relevant. As such in recent times fears that they are overly conservative has given rise to the trend towards risk-based inspection of steel elements in hot Hydrogen service

Early stage detection of HTHA is considered to be a challenge, due to the comparatively small size of methane voids vs typical ultrasonic wavelengths. One development from our supplier GB Inspection Systems has been the introduction of the TULA ultrasonic probes (patent pending). TULA applies Time of Flight Diffraction at ultra-low angles from the normal axis. It is a simple yet highly sensitive approach to screening for HTHA and is complementary to existing techniques such as PAUT, TFM and traditional TOFD. Operating at similar angles to dual element transducers, TULA transducers are designed with differing focal points allowing the user to focus at various depths. The TULA concept has also been applied to angle beam probes for the purpose of detecting HTHA in the HAZ of welds. Coupled with operator training and complementary methods, TULA is a powerful ultrasonic tool in the detection of HTHA.

Video: PCTE-Industrial's Metal Hardness Testing Basics

PCTE-Industrial was proud to present a special webinar this month, highlighting the Equotip Portable Hardness Tester. The webinar was hosted by our very own WA/SA Sales Manager, Warren Villarosa (NDT Level 3 Specialist - ISO 9712 & ASNT). We will be following this webinar up with an informative demo video on the Equotip 550. For a more detailed overview please see below:

Part 1 - Basics of Portable Hardness

- Definition, Applications and Traditional Methods

Portable Hardness Method- Leeb

- Technical explanation, advantages and limitations of methods, Leeb impactor options and accessories

Portable Hardness Method- UCI

- Technical explanation, advantages and limitations of methods, Leeb impactor options and accessories

Portable Hardness Method-Rockwell

- Technical explanation, advantages and limitations of methods, Leeb impactor options and accessories

Equotip Range

- 550, 540, UCI Live, Leeb Options, Rockwell