NOVASCAN

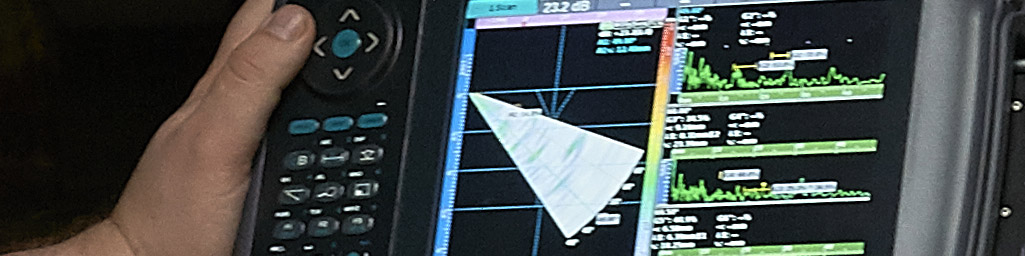

Portable ultrasound phased array flaw detector

New Phased Array Flaw Detector with TFM/FMC

New Phased Array Flaw Detector with TFM/FMC

Novascan is a full-featured phased array inspection instrument that displays multiple ultrasonic cross-sectional images producing accurate measurements. Phased Array inspection incorporates multi element probes to scan components at greater speeds than conventional ultrasonics. In addition to the phased array function and two-channel TOFD probes, it also supports the latest inspection techniques being Total Focusing Method imaging (TFM) and Full Matrix Capture (FMC) data acquisition. The number of imaging points is 1024x1024, which greatly improves quality and gives greater probability of detection for smaller defects.

Dual Role

The Novascan has a Field Programmable Gate Array (FPGA) connection interface, which suits both field and laboratory applications. The fast signal processing is an advantage for on-site inspections saving time and generating efficiency. It also allows the instrument to transmit the underlying data to the user, making it easier for users (such as research institutes and universities) to conduct secondary development.

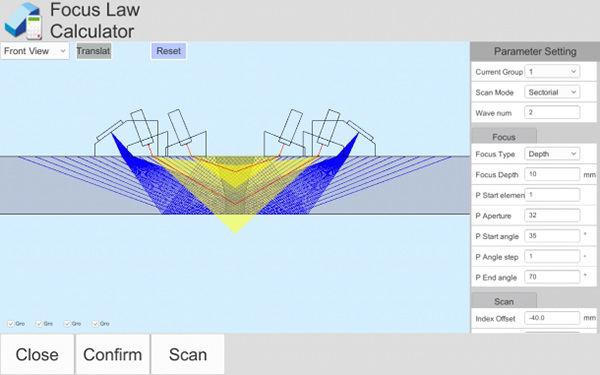

Powerful Scanning Simulation Function

Equipped with a new scan planning process, Novascan can realize 3D focus law simulation, multiple groups of simultaneous simulation and greatly simplify the user setting interface. This allows a quicker and efficient process simulation and calibration in the shortest time.

More Application Fields

The Novascan is equipped with a two-dimensional coded interface, which facilitates high-speed two-dimensional scanning and supports DLA and DMA probes. Both can be used for austenitic stainless steel inspections. With 32 groups for simultaneous detection and 8 groups displayed on the same screen, it is more than capable for complex analysis/detection applications.

-

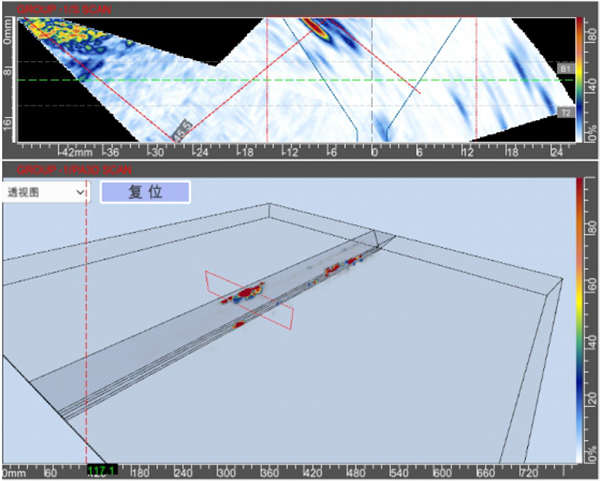

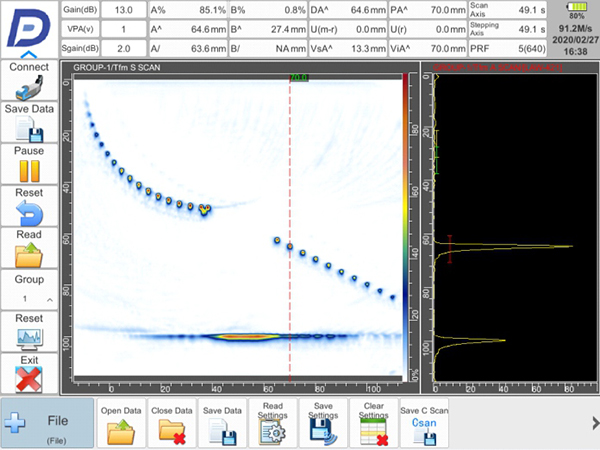

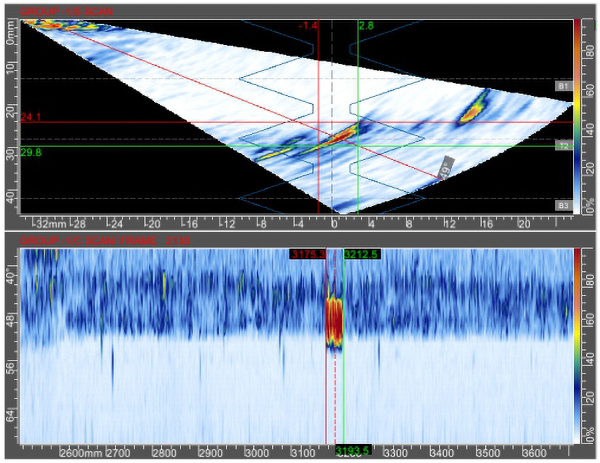

Real-time 3D imaging

The defects are displayed in real-time 3D. Meanwhile, the S-scan and A-scan can also be viewed, to help confirm signal interpretation. This allows for fast & intuitive defect detection. The 3D diagram can be rotated to allow full rotation to view the defect from any angle. To aid analysis of the defect, a data scanning line can be dragged onto the the 3D diagram which will show the S-scan and A-scan information. -

Two-dimensional scan

For high-speed two dimensional scanning a Dual-axis encoder can be used . It is recommended to utilise the Doppler dual-axis scanning system as it is matched to the encoder with little set-up required. The length of X axis can be customized, and the step size of Y axis does not need to be set for Y axis. The system automatically recognizes the step size of Y axis, and displays the data after processing in a two-dimensional scanning map. The maximum size Scanning map is 30M x 10M (X x Y). -

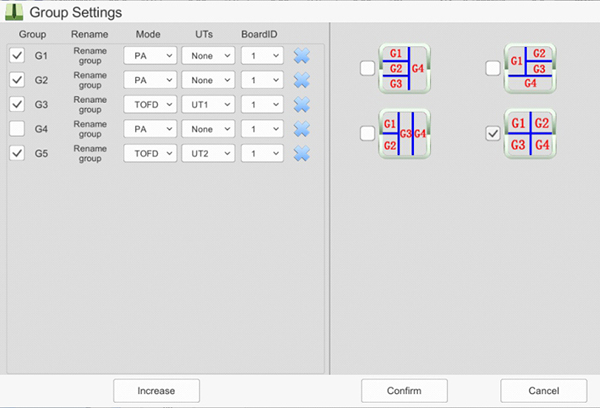

Multi-group simulation

Novascan software supports multi-group focus simulations to demonstrate PA and TOFD ultrasonic beam coverage. By selecting the Parameter Settings button, the inspector can set or change the values to assist the interpretation or analysis data. -

Multi-group ultrasound scan

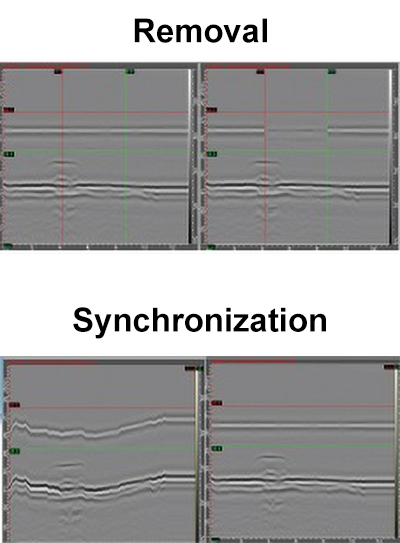

Multiple groups are scanned in parallel at the same time. Up to 32 groups can be set with the maximum focal laws for all groups not exceeding 512. Multi-group synchronization can adjust the individual parameters of any group. The individual parameters of all groups will be adjusted together. Scan axis synchronization, moving the position cursor of a group’s scan axis will drive the synchronous movement of the position cursors of all groups’ scan axes. -

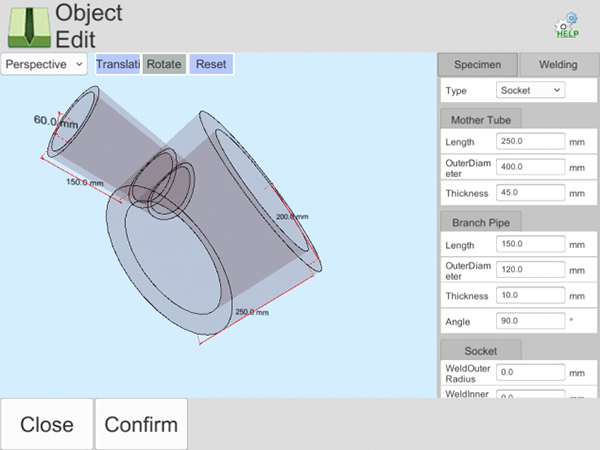

Specimen welding simulator

Test component types are optional: Plate, Round Tube, Square Tube or Socket. Set corresponding parameters to generate a 3D preview, to allow viewing from different angles, such as top view and front view. The simulation supports a display of 3D specimen welding, S scan of 2D specimen and cross-section simulation of weld being inspected. -

TFM/FMC

TFM is a new inspection method using Full Matrix Capture (FMC), which has the advantages of higher accuracy, with improved resolution for smaller near-surface blind zones, creating a larger scan range than conventional phased array inspection methods. This then increases the probability of detecting High Temperature Hydrogen Attach (HTHA). With ongoing continuous development of the Novascan, the issue of dealing with large inspection data can be resolved. -

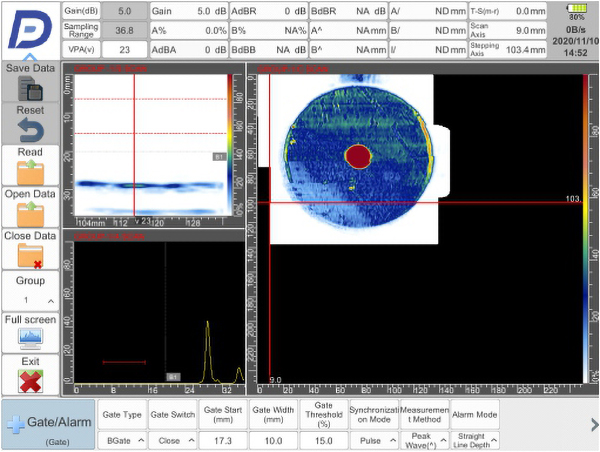

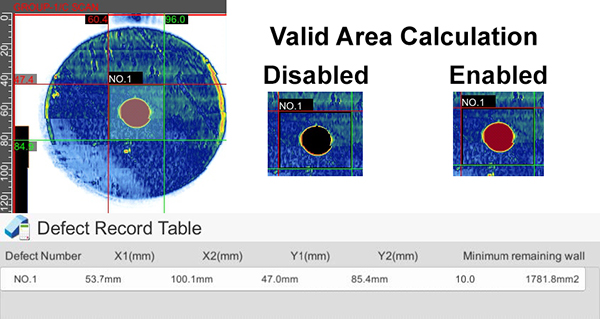

Area Calculation

Defect sizing is required for corrosion inspection, where a defect is selected and framed in C-scan and the area of frame selected is calculated automatically. To aid efficiency, the generated defect list is recorded in excel after the recording is merged and exported along with the report. -

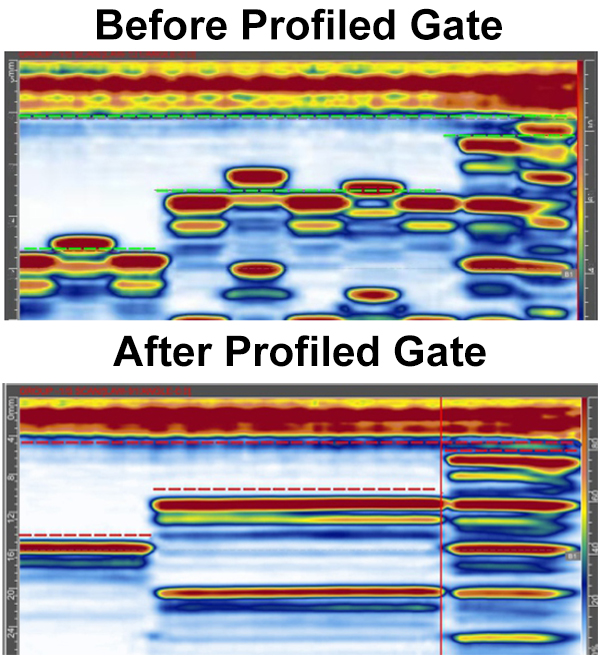

Multiple Gate mode

The Novascan supports several different gate modes including: straight gate, curved gate, rectangular gate and profiled gate. The user can select a nominated area to collect data according to the defect characteristics of the test component. Interference signals are removed to obtain a pure C-scan image. This greatly reduces the difficulty of defect evaluation and is particularly suitable for complex geometry components. -

PA mode data analysis

For PA linear scan inspection data (e.g. corrosion inspection data), click Measurement > Area Calculation to identify the corrosion defects in the C-scan and S-scan. The software automatically calculates the corrosion area and records it in the report. -

TOFD mode data analysis

The NOVASCAN can perform lateral wave synchronization and lateral wave removal. Defect length and depth can be determined easily. -

Offline analysis

The off-line software is the perfect PC-based software complements the Novascan instruments, and seamlessly imports files for advanced processing and analysis. A total of 18 display modes are available, supporting simultaneous display of 4 sets of data. Facilitating image enlargement, it can quickly locate and quantitatively measure defects. Supports a variety of standards, allows the assessment of the defect grade discrimination. A variety of weld illustrations and CAD files can be imported to assist in defect identification.

Specifications

| Phased array channel | Conventional channel | ||

| Configuration | Reception/transmission | 32/128 | 2/2 |

| Detection range | 9900–s | 9900–s | |

| Sound velocity | 340-15240m/s | 340-15240m/s | |

| Inspection mode | PE/PC | PE/PC/TT/TOFD | |

| Pulse voltage | 50V/100V | 100V/200V/400V | |

| Pulse generator | Pulse mode | Negative square wave | Negative square wave |

| Pulse width | 30-1000ns, step of 2.5ns | 30-1000ns, step of 2.5ns | |

| Pulse rise time | <8ns | <10ns | |

| PRF | 20kHz | 20kHz | |

| Delay | 0-20μs/2.5ns | 0-20μs/2.5ns | |

| Receiver | Gain range | 0-120dB | 0-120dB |

| Bandwidth | 0.5-15MHz | 0.5-20MHz | |

| Receive delay | 50μs/0.1μs | 50μs/0.1μs | |

| Data acquisition | Sampling rate | 100MHz | 100MHz |

| ADC resolution | 10bit | 12bit | |

| Focal law number | 512 | NA | |

| Focus type | True depth/half sound path/projection/any surface | NA | |

| Detection | FW/HW+/HW-/RF | FW/HW+/HW-/RF | |

| Scan and display | Scan type | Sectorial/linear scan | NA |

| Display mode | A/B/S/C/3D/TopC | A/B( TOFD) | |

| Measurement unit | mm | mm | |

| TCG | Point number | 16 | 16 |

| Maximum gain | 40dB | 40dB | |

| Maximum gain slope | 40dB/μs | 40dB/μs | |

| Inspection report | WORD mode | ||

| Data storage | Pluggable memory | USB / SSD (built-in) | |

| Screen | Size | 10.4 inch | |

| Resolution | 1024*768 pixel | ||

| View area | 211mm*158mm | ||

| Type | IPS capacitive touch screen | ||

| I/O interface | USB 3.0 | 2 pcs | |

| Ethernet | 2 pcs; up to X86, 1000 Mb/s; down to FPGA, 1000 Mb/s | ||

| WIFI | 2.4G/5G dual band, 150 Mb/s | ||

| Video output | HDMI1.4b | ||

| Encoder | LEMO 16-pin | ||

| Language | English/Chinese | ||

| Power supply | DC supply voltage | 15V DC 100W | |

| Battery type | One 11.25V 99.6Wh lithium battery Continuous working time about 4 hours | ||

| Enclosure | Size | 360mm*260mm*130mm | |

| Weight | 6Kg (excluding battery), 7Kg (including battery) | ||