UT8000 Ultrasonic Flaw Detection

Compact, Durable and Adaptable

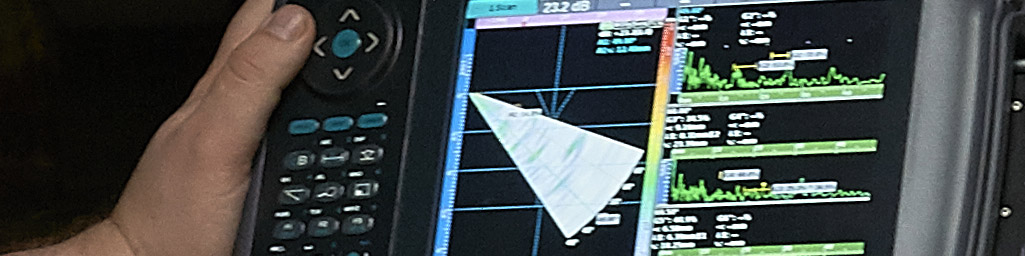

Proceq's UT8000 is a new generation of Ultrasonic Flaw Detector. It places a pulser-receiver module in a portable, lightweight control box, compatible with all standard UT probes.

Proceq's UT8000 is a new generation of Ultrasonic Flaw Detector. It places a pulser-receiver module in a portable, lightweight control box, compatible with all standard UT probes.

The brilliant UT8000 Live software is available for Apple iPad devices, with unique market leading features such as a comprehensive logbook, time rewind to record echo dynamics and the fastest DAC curve on any device.

The pulser-receiver unit has two distinct pieces, the battery pack and the pulser-receiver. Without the battery pack the pulser-receiver is light enough to mount on most standard drones. The unit is IP67 rated and Mil-STD drop tested.

The Pulser-Receiver specs are as follows:

Video

Flexible Power

Comes with a quick switch bayonet style removable battery pack of 6x rechargeable AA batteries.

- Battery pack uses standard AA batteries - Easy switch out if there is no time for charging

- Can use an external USB power bank as another power solution

- Flexible power and weight options for drone or rover mounting.

- Battery pack is a simple bayonet twist and pull, carry a spare and be back in action in seconds.

Flexible Screen Capability

Users can choose from the full range of Apple iPad devices. With Apple’s high quality screen technology users have the best screen available on any UT set:

- Adapt screen choice to the application. Mini for tight spaces, iPad pro for no compromises.

- The iPad Pro refresh rate of 120Hz is faster than anything other screen available.

- Broken screen? They are available at a store down the road, back on the job in hours rather than waiting weeks or months for a repair.

Workflow Possibilities

With the right combination of apps the technician will be able to issue reports directly from the iPad. Not only is the UT8000 compact, but the iPad can eliminate the need to carry laptops, paper standards, a camera and paper notepads. The UT8000 and and iPad can easily be carry on luggage, eliminating any stress from equipment transport while still allowing the technician to have everything they need with them.

Connectivity

Adaptable connectivity

Like other equipment in Proceq’s Live Range the UT8000 can be connected via WiFi. UT8000 can also be connected via cable for scanning with undetectable latency if required.

Why Wireless?

- Mounting on a drone, to conduct thickness surveys remotely

- Mounting the pulser-receiver on one end of an extension pole and the iPad on the other, allowing the technician to get readings on areas that are just out of reach or to avoid bending.

- Mounting the UT8000 on a wheel probe, allowing the technician to get readings down vertical drops, such as tank strakes or vertical pipework.

- Collaboration between a rope access tech and a more experienced NDT specialist.

Why Wired?

- Fastest possible response time

- Lowest Latency

Cloud Technology

Being part of Proceq’s live family the UT8000 can be connected to the cloud, allowing easy sharing of report information inside or outside a company and even the possibility of another technician dialing into the iPad and assisting with interpretation remotely.

Software

User Interface

Commonly used functions are tied to gestures. Some examples are:

- Vertical swipe for Gain

- Horizontal swipe for Zero offset

- Horizontal pinch for Range

- Drag and drop gates

- Tap for DAC points, record and removal.

The user interface is one of the main selling points. New technicians and old will find the learning curve very simple and operation intuitive.

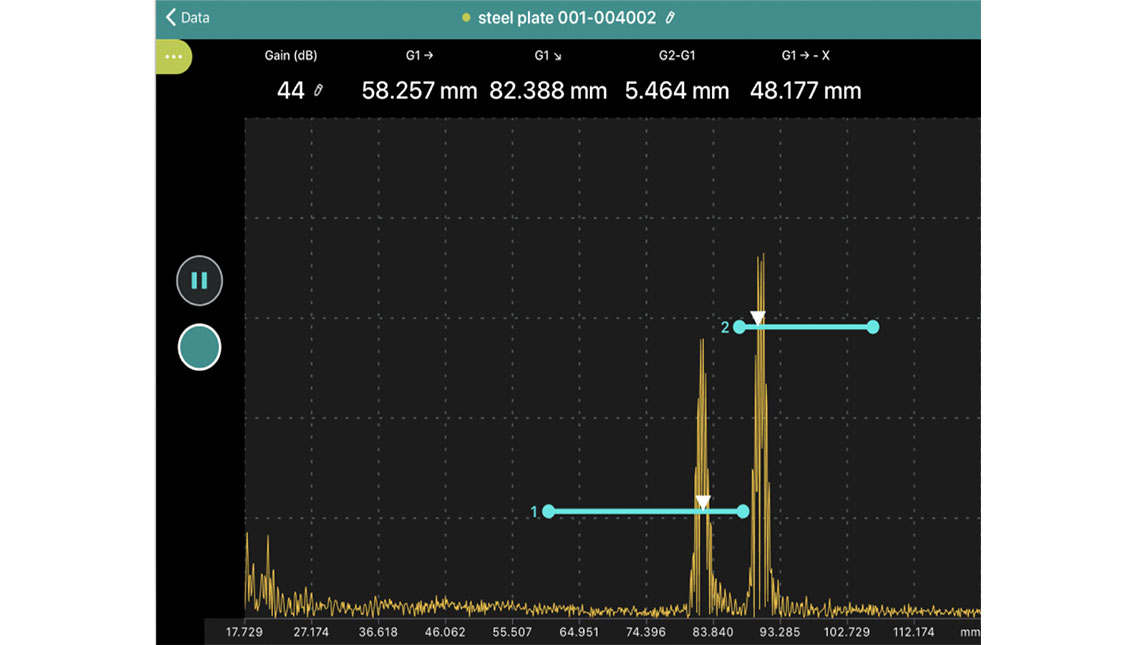

Flaw Detection

The User Interface makes set-up for flaw detection straightforward, Proceq has added tools to assist with reporting and recording.

Flaw Table

A flaw table is used to record information regarding the reportable flaws detected. This integrates with the logbook functionality and includes the time rewind information. When the technician exports the logbook not only does it include the metadata like serial numbers, settings, location etc, it also includes all information input into the flaw table. Including the time rewind.

Time Rewind - Echo Dynamics

Time Rewind - Echo Dynamics

Time rewind is a very useful tool. The way a flaw behaves on screen when scanning in a certain direction (transverse, raster, lateral & orbital) is a large part of the classification of the flaw. This behaviour is what referred to as the echo dynamics and a single photo rarely captures this. With the rewind function the technician has the ability to press record and the set will recall a few seconds prior and up to the time the technician stops. This means that the technician can capture the full echo dynamics and include that as justification for their interpretation. This item is unique to the UT8000.

Corrosion Surveys

The UT8000 has a flexible grid function. This is very important for closed or open grid corrosion surveys. Before the UT8000 sequential data logging required technicians to plan out the grid and work along step by step. Now the user can define a grid size, its resolution and take a survey as they see fit. If there is a part of the grid they want to correct, they just tap and re-take the reading.

Traceability

The UT8000 has huge potential for streamlining the UT workflow and making everything more traceable. One of the biggest weaknesses of standard UT work is its traceability and the UT8000 addresses that. The logbook records metadata, notes and photographs of test positions and all changes made during the inspection. When the Technician exports this logbook, its is a full snapshot of the inspection, from start to finish. There can be as little or as much detail in this as a company’s internal procedures call for.

With the right workflow, a company can capture every single piece of information that they require to issue a report.

Hot Swapping & Benefits for Technicians

UT technicians can set up their own accounts, keeping backed up record of their unique settings and inspection logs. Another technician can use the same iPad and log in with their account and switch to their settings.

When it comes to the increasing difficulty of record keeping with certification, The UT8000 accounts records serve as a log for the time a technician has spent doing UT.

Accessories

Tablet Holder

- Adjustable view

- Can act as a stand either supported on a flat surface or by the UT8000 itself.

- When attached to the UT8000 can fold flat, keeping the UT8000 in intimate contact with the tablet.

- Can be mounted on ferromagnetic surfaces using the rare earth magnets.

Battery Pack