Ultrasonic Scanners and Crawlers

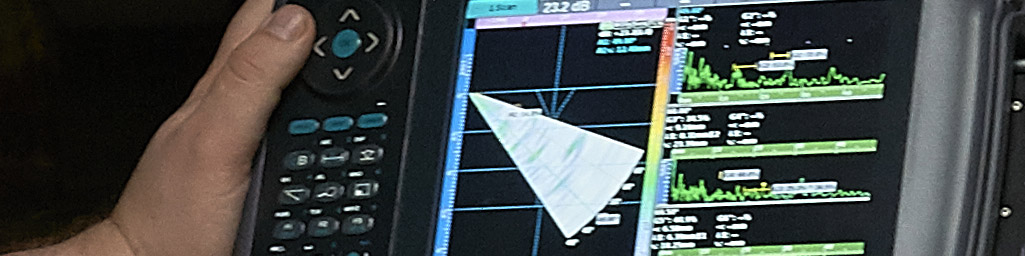

Scanners are a useful tools to aid in accurate inspections by positioning and controlling the placement of probes and wedges for Phased Array and Time-of-flight-diffraction (TOFD) weld inspection. NDT industrial scanners can be used across a wide range of aerospace and industrial applications to improve speed, data quality, and the probability of detection (POD). Doppler offer industrial scanners with one or two axes (XY) in both manual and motorized models.

A variant scanner is the corrosion inspection scanner which can be used on pipes or flat surfaces. To increase accuracy scanners can be coupled with encoders. Other accessories include adaptors and water pumps.

Examples are:

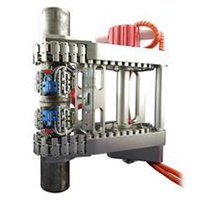

The DSC-06 Corrosion scanner uses a water bath as the transmission medium for the sound waves.

FS-04/05 Tubule Corrosion scanners are suitable for corrosion detection of small diameter pipe in OD40mm~OD150mm diameter range. The scanner is equipped with encoder, and the magnetic wheel absorbs the steel pipe with stable coupling and simple operation.